3D printed structures, like houses, office buildings, and bridges are much more common than they were even a few years ago, and a construction company in Vancouver is introducing new disruptive technology that can accelerate the building process exponentially. Vancouver-based LifeTec Construction Group Inc. is working on several private projects with its technology, which can 3D print studs out of structural steel for home construction.

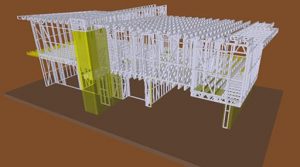

Most typical 3D printing processes for metallic materials, like steel, shape the material with lasers, which makes the printers get extremely hot, but LifeTec, which was founded earlier this year, uses the end-to-end design and build Framecad system. The advanced Framecad allows for quality buildings to be constructed rapidly. The company’s process is totally mechanical – instead of using specialized 3D printers to make individual modular parts, studs and panels, the building frame is designed on a computer. Then, the parts are shipped to the construction site and assembled there. Not only is 3D printed steel more durable, environmentally friendly, and resistant to warping and mold than wood, it offers shorter construction time. In terms of production-line steelmaking equipment, a single 3D printing machine takes up much less space.